Make Robots Great Again

While China runs away with the manufacture of industrial robots and its use in its factories, America is still looking for ways that "real" men can twist small screws into chassis

The first robot manufacturer I ever visited in China wasn’t just a lone inventor in a cramped garage—it was ten young engineers collaborating in one oversized workshop. I was hunting for companies making robotic arms for manufacturing that a client was on the hunt for.

Inside, lean teams of young men hunched over benches, carefully assembling robot parts. The assemblies looked so precarious that their creations threatened to collapse before completion. Nearby, two middle-aged businessmen advised a technician on the nuances of getting a robot arm’s movement just right. That hands-on, frenetic energy stayed with me.

A few weeks later, I attended a major industrial robot expo in China, and my perspective changed entirely. The speed, drive, and ambition on display made it clear: China was rapidly catching up with the world’s manufacturing powerhouses.* That was 15 years ago.

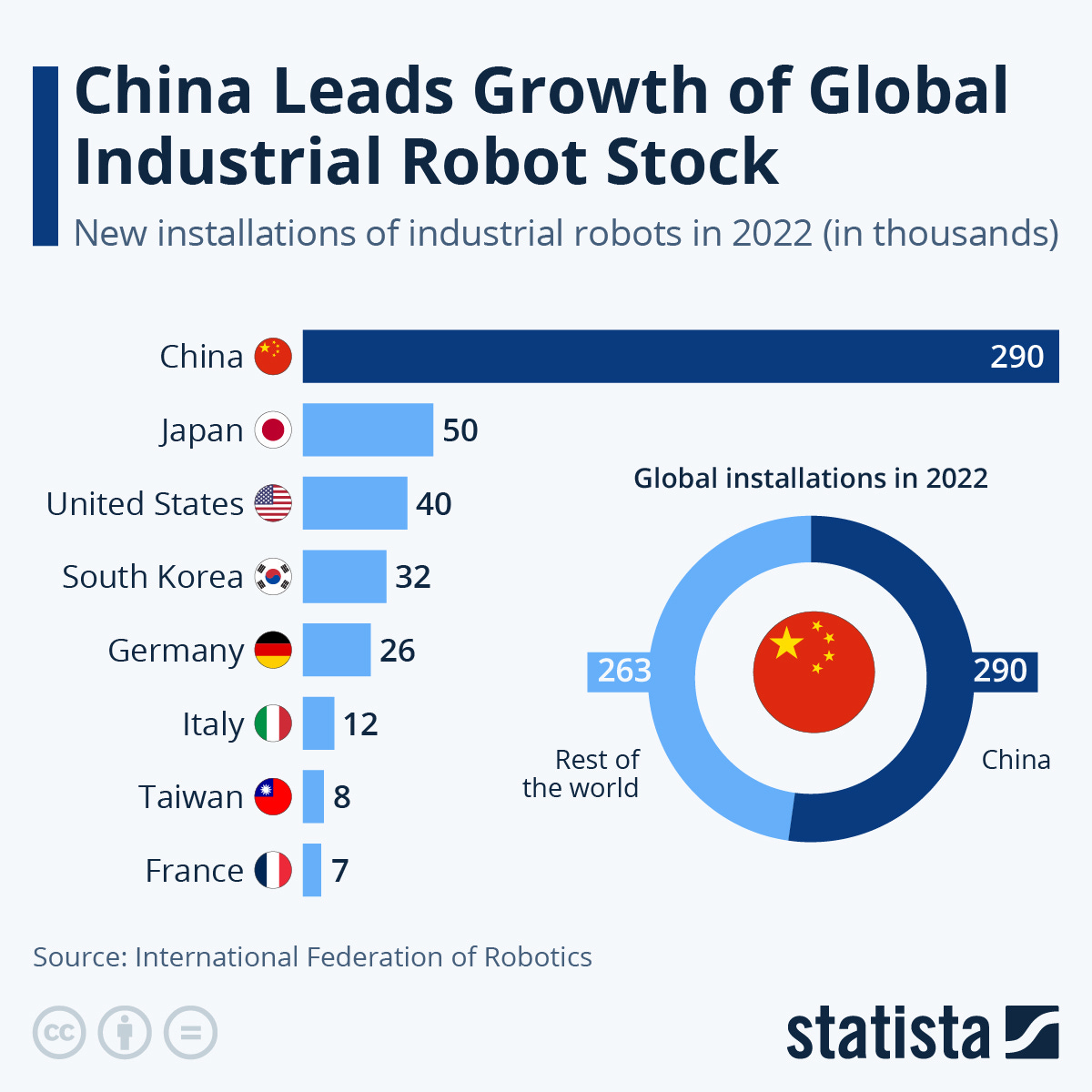

Today, China has leapfrogged ahead. According to the New York Times, China last year installed almost 300,000 domestically made robots in its own factories. The United States installed just 34,000 in 2024.

China boasts nearly 2 million manufacturing robots, and now produces close to one-third of all manufactured goods globally—more than the United States, Germany, Japan, and the UK combined.

But China’s transformation comes with new challenges. The country now has an abundance of university-educated young people struggling to find jobs. Twenty years ago, when China leaned into “Opening Up” to the world, manufacturing jobs were everywhere, and cities on the eastern seaboard teemed with migrant workers chasing opportunity.

Those days are gone. Today, Chinese factories have upgraded to producing higher-quality, more sophisticated products. National policy continues moving factories inland for lower costs or outsourcing operations to places like Vietnam, Cambodia, Laos, and Mexico.

This shift has left millions of young Chinese caught in a kind of labor “twilight zone.” Traditional manufacturing jobs have disappeared, and while the east coast edges from “developing” to “developed,” new graduates often lack practical training for available roles.

Yet, China’s robot revolution rolls on. Last year, China surpassed Japan to become the world’s largest exporter of factory robots, with its global share rising from a quarter to over 30%. Meanwhile, Japan’s portion fell from nearly 40% to 30%. Against this backdrop, promises from President Trump’s administration to bring manufacturing and factory jobs “back to America” sound out of step with reality. The world has already moved on. To robots.

The hands that once maneuvered small screws into a variety of wares in China’s booming factories are no longer needed. That era has ended; there’s no going back — for China, and certainly not for America.

Should we, then, feel optimistic, anxious, or simply amazed at how far China has come?

Though perhaps the greater consideration is that there are those in America who want us to pick up China’s mantle as the once-premiere producer of manual labor.

Seems like a non-starter to me.

*You can read more about my experiences with and observations about technology development in China in my book, “China Fast Forward: The Technologies, Green Industries and Innovations Driving the Mainland’s Future (John Wiley & Sons, 2012).